NOISE INSULATION MATERIALS

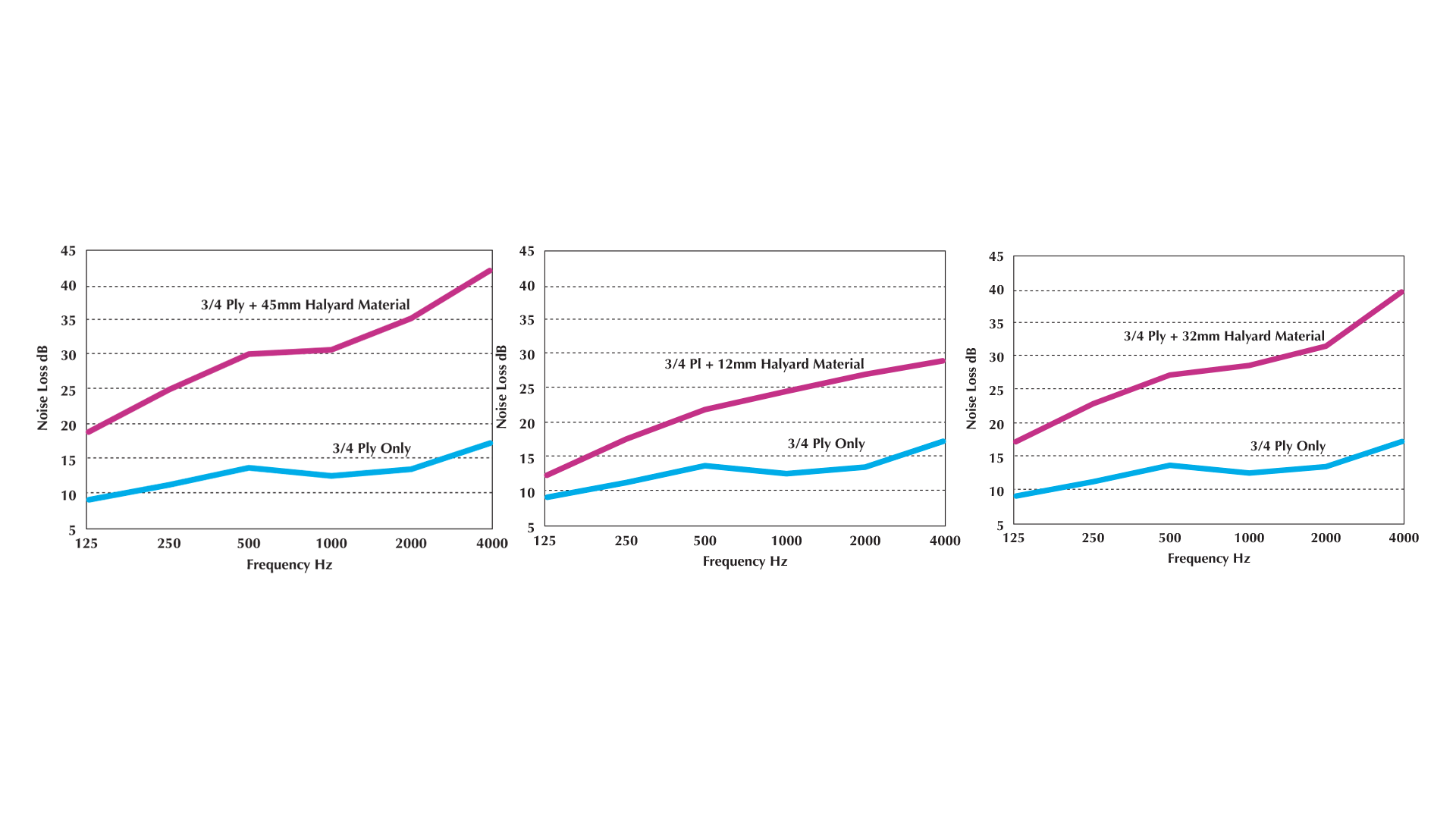

Marine diesels create very high noise levels – often well over 100 decibels. Engines are always located close to the boat user, generally in engine spaces made from GRP, timber, or steel. Noise insulation changes all this. It adds a soft facing to hard bulkheads to absorb noise and stop it bouncing around and growing. It features a clever multi-layer construction to make a thin material more effective than simple insulations many times thicker

Halyard Noise Insulation uses high performance barrier materials to achieve excellent acoustic results with low frequency noise associated with diesel engines and other onboard noise generating equipment

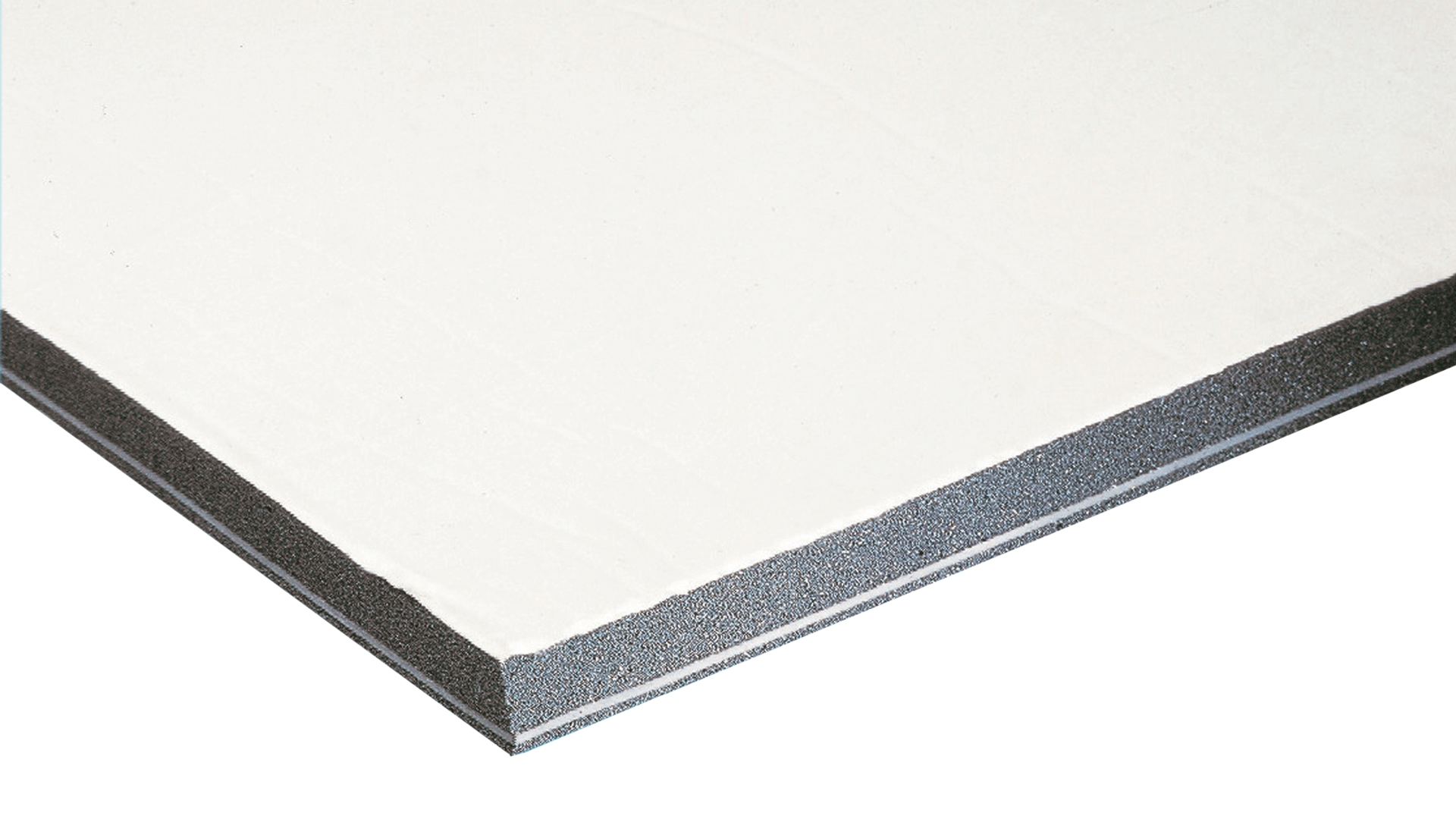

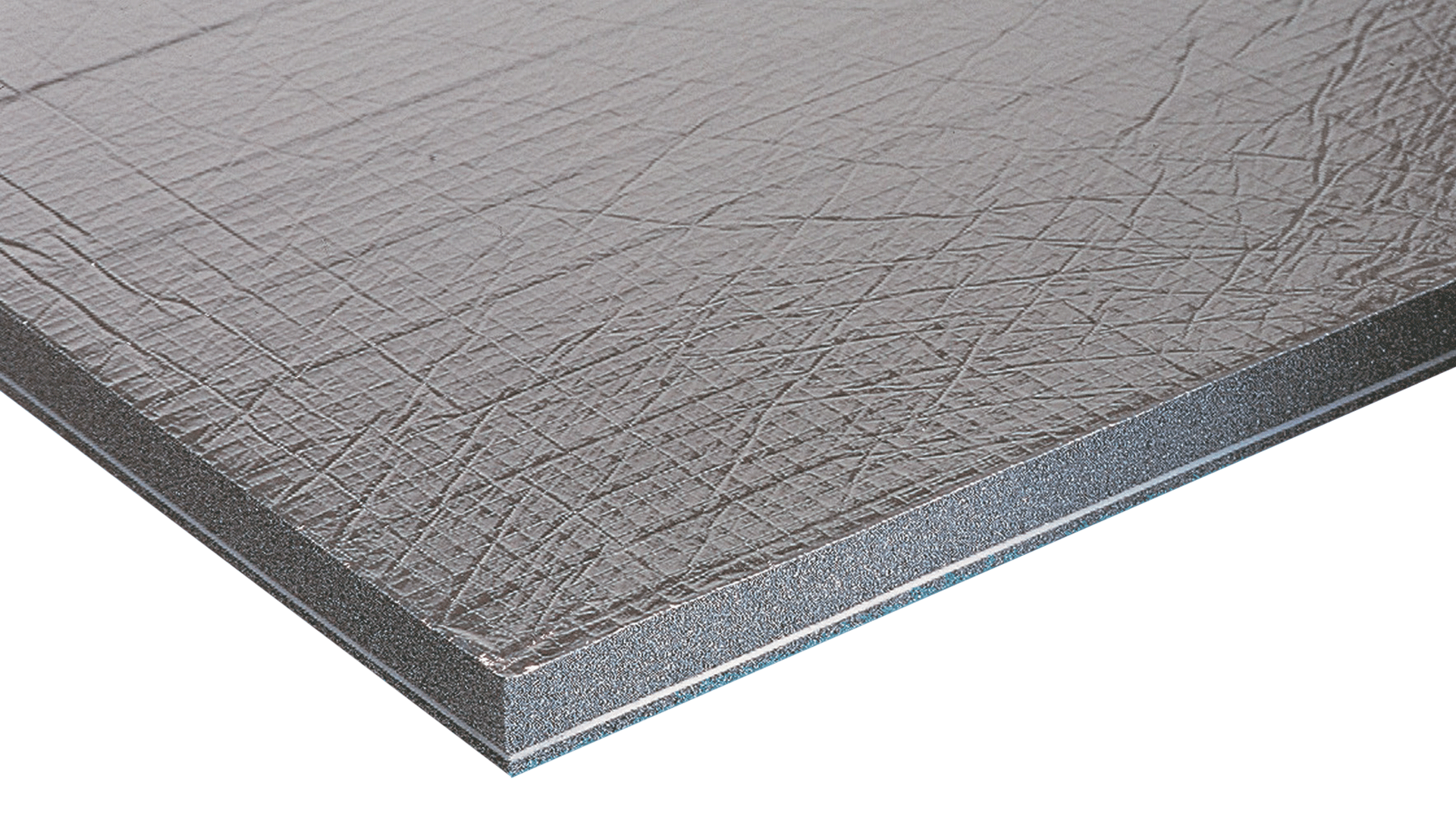

• The absorption layer A thick layer of fire zero rated foam which soaks up noise and stops it bouncing around the engine space.

• The transmission layer A high density barrier provides the highest possible mass and gives the best noise reduction. The damping layer weighs 5kgs per square meter – more than the lead sheet used in older materials.

• The isolation layer This thin layer of foam has a crucial function: It acts like the gap in double glazing and stops the noise which hits the transmission layer being carried through to the bulkhead.

Packing (12 mm and 32 mm materials)

12mm and 32 mm (½” and 1 ¼”) materials are packed four sheets to a box. Each sheet is 1000 mm x 600 mm (39” x 24”) making the total area 2.4 sq. meters (26 sq. ft).

Box weight is approx. 14 kg for 12 mm and 19 kg for 32 mm

Packing (45 mm materials)

45 mm (1 ¾”) materials are packed two sheets to each box. Each sheet is 1000 mm x 600 mm (39” x 24”) making the total area 1.2 sq. meters (13 sq. ft).

Box weight is approx. 16 kg